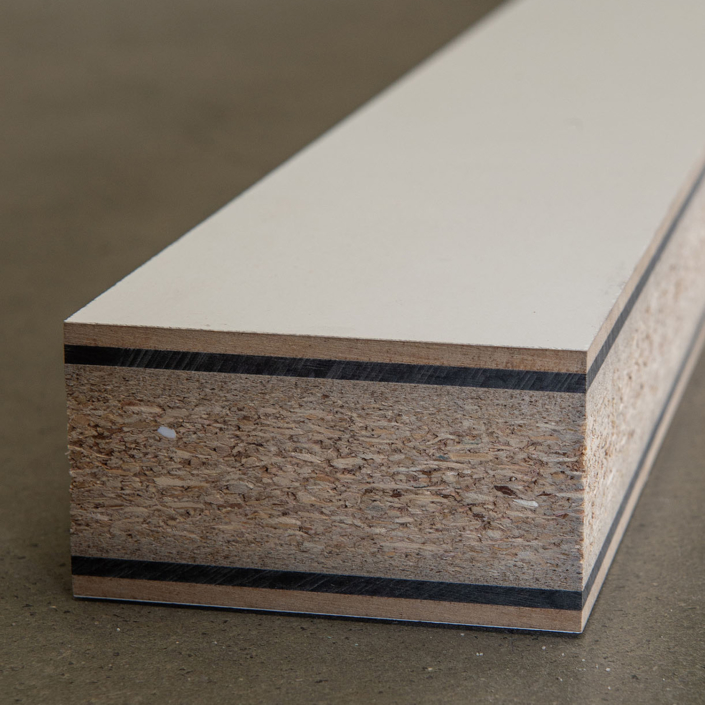

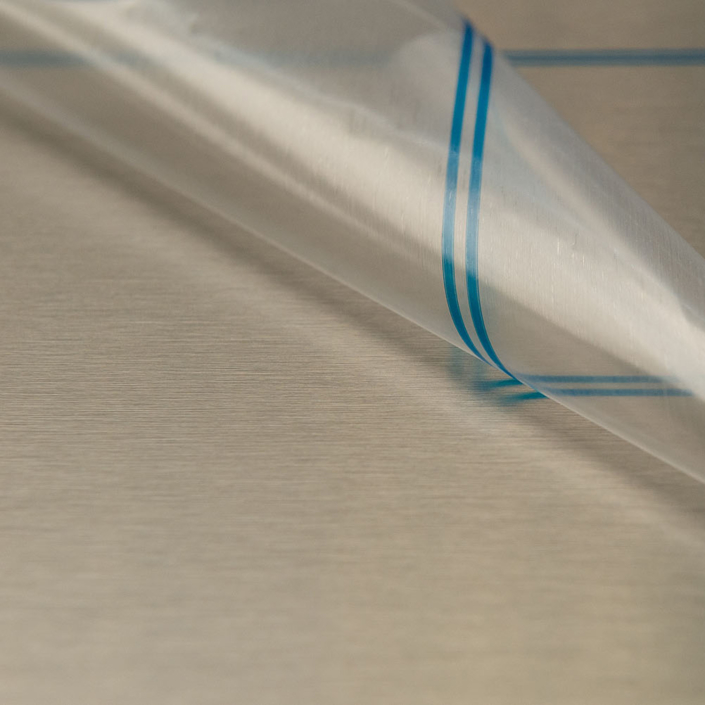

Melaplan compound elements are produced by glueing and pressing melamine laminates onto base materials. All common particle boards, hardboard-, plywood-, multiplex-, MDF- and plaster boards can be used. Solvent based adhesives (PVAc-glue) of type D3 are normally used for the glueing process.

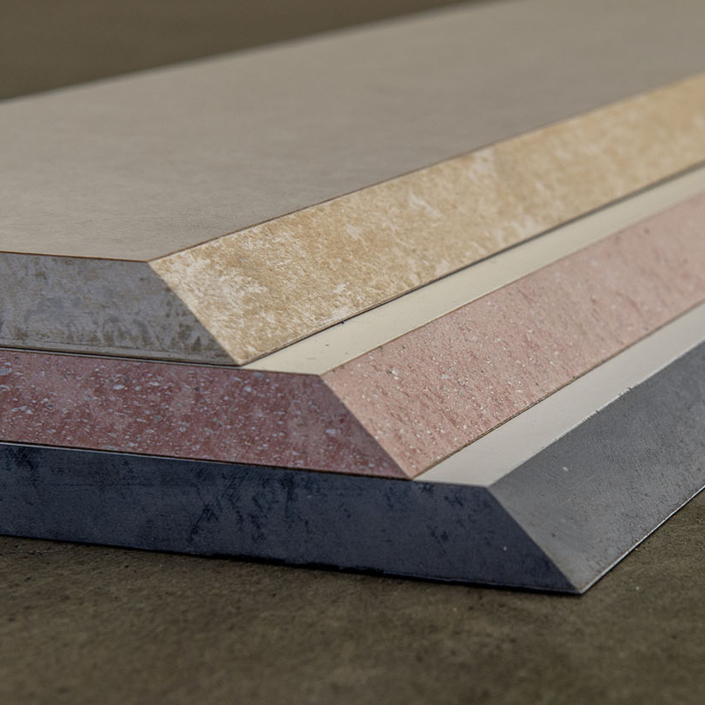

Melaplan compound elements show – acc. to their usage – very good performance characteristics, such as high abrasion-, scratch- and shock values as well as a high light resistance factor. They are used as flooring elements, working table tops, window sills, table tops fronts and partitions as well as for staircases and staircase renovations for the whole furniture industry and the interior design.

Melaplan compound elements are available in thicknesses of 3 – 65 mm.

The max. length is 5.600 mm and the max. width is 1.600 mm.

We also offer job order production.